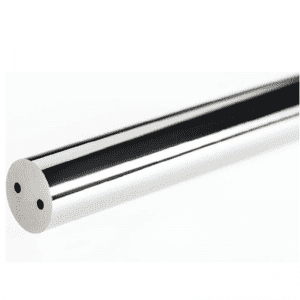

ٽنگسٽن سولڊ ڪاربائيڊ روڊز لاءِ آخر ملز ۽ مشقون مستحڪم اعليٰ معيار سان

1.The tungsten سڪل carbide rods molding يا extrusion ذريعي molded پريس آهي.

2. ٽنگسٽن سڪل ڪاربائڊ روڊن کي گھٽ دٻاءُ واري sintering انٽيگريٽڊ فرنس ذريعي sintered ڪيو ويو آھي، اھڙي طرح مجموعي ڪارڪردگي اعلي آھي.

3. The rough tungsten-cobalt carbide گول بار، يا گول بار جي ٻاهرئين قطر کي ڪنهن به رواداري جي مطابق بهتر ۽ پالش ڪري سگهجي ٿو. عام tolerances h5،h6، -0.005، وغيره آهن، ۽ carbide rods آخر chamfer به عمل ڪري سگهجي ٿو.

4.Carbide rods عام اسٽيل، اڇلائي لوهه، stainless اسٽيل، گرمي مزاحمتي اسٽيل، nickel بنيادي ۽ titanium مصر جي پروسيسنگ لاء مناسب آهي. عام مقصد لاءِ تجويز ڪيل ڪاربائڊ ٽول مواد جهڙوڪ ٽوسٽ ڊرلز، اينڊ ملز، نل ۽ گن ڊرلز.

اسان جي ڪاربائڊ روڊن جا قسم

1. اڻڄاتل ڊگھو رنڊڪ

| TOL. اڻڄاتل ڊگھي ڇنڊن جو | ||

| ماپ (DxL،mm) | رواداري | |

| ڊي (ايم ايم) | ايل (ايم ايم) | |

| ڊي[1-3)x310/330 | 0.30 ~ 0.55 | 0.00~+4.00 |

| ڊي[3-12)x310/330 | 0.30 ~ 0.60 | 0.00~+4.00 |

| ڊي[12-20)x310/330 | 0.30 ~ 0.65 | 0.00~+4.00 |

| ڊي [20-40]x310/330 | 0.30 ~ 0.70 | 0.00~+4.00 |

2. اڻڄاتل ڪٽ کان ڊگھي رنڊڪ

| TOL. اڻڄاتل ڪٽ کان ڊگھي ڇنڊن جا | ||

| ڊي / ايل (ايم ايم) | D&L جو TOL.mm ۾ | |

| ايل <=70 | 70<L<=150 | |

| D<5 | D(0.20~0.30), L(0.20~1.5) | D(0.25~0.35), L(0.20~1.5) |

| 5<=D<40 | D(0.25~0.35), L(0.20~1.5) | D(0.30~0.40), L(0.20~1.5) |

3.Ground long rods

The tolerance of the long rods is h5/h6 or at customer’s requirement in Dia. ,and 0.00~+5.00mm in Length as normal.

4.Ground cut-to-length rods

The tolerance of the ground cut-to-length rods is h5/h6 or at customer’s requirement in Dia. ,and 0.00~+2.00mm in Length as normal.

5.PCB Rods

more than 50 years production and management experience,Advanced production technology, High-precision machines, Strict QC management system, Special-designed packing boxes and tubes, Various shipping methods

1.Tungsten carbide blanks production

Good quality carbide products rely on 100% virgin raw materials and advanced wet-milling,pressing machines and sintering furnaces. We put emphasize on every production process of our carbide blanks. To keep good quality of carbide blanks is the base of furtherly machined high precision finished carbide parts.

2.Inspection and testing process

In order to ensure the quality of all our tungsten carbide finished products, a very strict QC management system we called “Quality Control Center” has been introduced. With our advanced inspection equipment and our professional inspectors, we are able to do raw materials inspection, on-site inspection and after finishing inspection to ensure 100% good quality of your carbide products.

3.Advanced CNC Equipment

NCC owns a series of high-precision grind machines, including flat grinding machines, OD and ID machines, Centerless grinding machines and customized grinders. Also we have CNC machines, EDM, Wire-cutting machines and drilling machines etc. With our skilled workers, we can control very high precision of each carbide part.

4.Packaging and Shipping

Special-designed packing boxes and tubes will be used properly for the standard and customized carbide products to ensure the safety of the goods during the transportation process.A wide range of shipping ways can be available for your shipments, for example we can ship goods by Sea, by air and by Express companies like DHL/FedEx/UPS/TNT etc.